The Bat of Your Dreams: Inside Demarini’s New Custom Bat Line

![]()

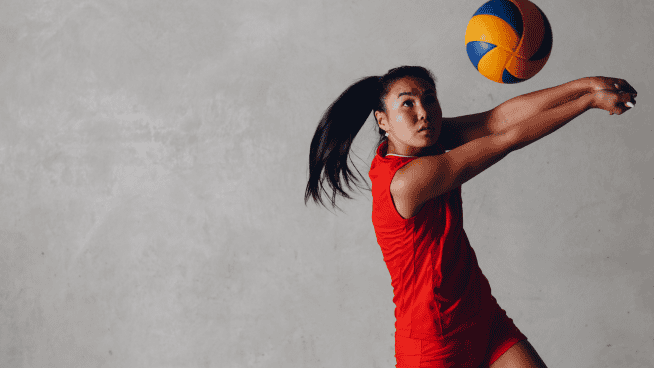

Baseball players always find a way to make equipment their own. Ballplayers have worn the same basic uniform (hat, jersey, pants, spikes, etc.) for the last century, yet they’ve found a surprising amount of creative freedom within the traditional garb of America’s pastime.

How do you wear your pants? How do you brim your hat? Do you like wristbands? Do you unbutton your jersey? Do you wear one batting glove? Two? No gloves at all? Small cosmetic details might seem unimportant to a spectator, but the extra sense of comfort or confidence they bring can mean the world to a player. In a sport where failing seven out of 10 times will put you in the Hall of Fame, confidence is an extremely valuable—yet elusive—part of the game. Gear isn’t just about looking good, it’s about feeling good as well.

With the launch of Demarini’s custom bat line, players now have another way to express themselves through their gear. In the past, every specific bat model looked the same—same color scheme, graphics, etc. If you wanted to make your bat unique, the best you could do was scribble on it with a sharpie or roll the handle with a different colored grip tape. Now, you can alter a bat’s color scheme to fit your taste—and you can add personal touches like your nickname, team name, numerals, etc.

STACK visited Demarini headquarters in Hillsboro, Oregon to find out more about their custom bat line.

Your Bat, Your Way

Customization is in Demarini’s DNA. The company was founded in 1989, when founder Ray Demarini started making custom bats in his shed for friends and teammates. Fast forward to today, and Demarini is one of the top bats in baseball and softball. Their focus is innovation driven by direct player feedback. College baseball powerhouses like Arizona State, LSU and Vanderbilt, as well as college softball juggernauts like Oregon, Michigan and Baylor, will swing Demarini bats in 2015.

It seems like custom bats would be a no-brainer. We’ve been able to customize and personalize our favorite sneakers for over 15 years. So why haven’t we been able to customize our bats until now? It turns out that making a bat is a complicated process, only further complicated by throwing customization into the mix. That’s why Demarini is the first company to offer truly customizable bats.

The custom bat website, demarinicustombats.com, is intuitive. You start by picking the model you like. Currently, only one model is available for both baseball and slow pitch. Fastpitch bats will become available for customization in April. Demarini says that more models will become available for customization shortly, and the number of customization options will also expand, meaning more colors, logos, graphics, fonts, etc.

Once you choose your model, you run through a checklist of bat components—barrel, end cap, handle, grip, graphics, etc.—picking the color you want for each. Toward the end of the process, you can insert a logo or custom text onto both the end cap and the knob. It’s a simple, fun process, and you can easily kill an hour or two bringing different design ideas to life. Once you digitally purchase your custom creation, the specifications of the bat are sent to the Demarini factory. Then the real work begins.

The Bat Cave

Demarini’s operations are spread across two buildings a couple of miles apart. The first building, known as D1, houses the company’s administrative offices, research & development, engineering, testing, shipping and final manufacturing. The second building, known as D2, is the main manufacturing facility. The fact that Demarini has all of this in one place makes them agile—they can dream up a bat, create it and test it in a single day.

Every Demarini bat starts at D2 in the form of a hefty, hollow chunk of cylindrical aluminum.

The building block of every Demarini bat

The bats are then sanded, smoothed and shined to remove any blemishes and imperfections. They also receive an interior winding that allows for the end cap to be screwed on later.

A Demarini bat after it’s been sanded and shined

Next, the bats are lined up and sent past a machine that applies a base coat, which helps the colored paint and graphics stick to the bat. The next step is different for custom bats and standard model bats. The standard model bats continue down the line and are sprayed with an identical base color. The photo below shows some 2015 Voodoo Overlord models being painted.

Paint being applied to a crop of Demarini 2015 Voodoo Overlords

Since each custom bat has a different color scheme, they cannot be painted en masse like the standard models. They are painted individually. Nearly 20 paint colors are currently available, including outlandish options like Vegas Gold and Neon Green. Paint used for Demarini’s custom bats is first hand-mixed and then applied by hand.

A batch of paint being mixed for use on a Demarini custom bat

The hand-painted approach obviously takes longer. In fact, a Demarini custom bat takes twice as long to make, with twice as many hands touching it, as a standard model bat. That extra TLC is a big reason why no company has offered custom bats until now. Demarini believes the extra time is well spent when the goal is to give players what they want.

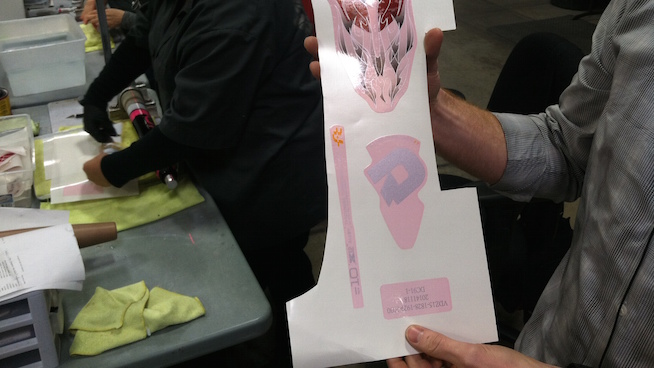

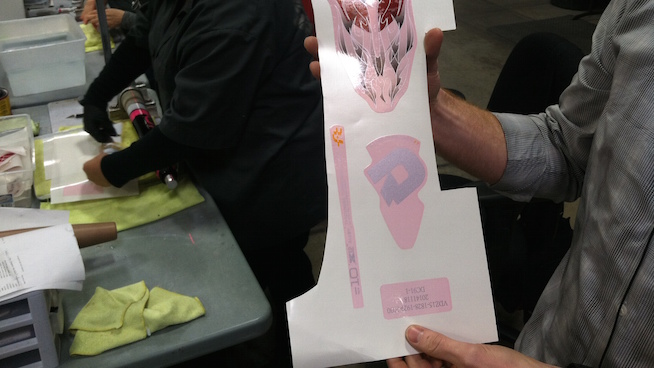

After a bat is painted, it’s put into a low-heat, industrial size oven for roughly 45 minutes while the paint dries. Next, the bat graphics are applied. Since a user can pick different colors for the lettering and graphics on a custom bat, each graphic must be carefully applied by hand.

Demarini custom graphics prior to being applied to a bat

This requires a delicate touch. Graphic appliers must go through six months of training. After the graphics are masterfully applied, another clear coating is put on the bat, which allows the paint and graphics to stay crisp and clear despite the immense beating the bat takes. The coating is also a UV protectant, ensuring the paint won’t fade after a couple of days in the summer sun. After that, the bat is carefully packaged so it can be transported to D1 for final assembly.

Back at D1, the bat handles are attached by a machine that applies a strong glue and affixes them to the bat barrels. The only parts of Demarini’s bats that aren’t built in-house are the end caps, knobs and handles. These are done by a nearby Hillsboro manufacturer. After that, the bat is placed on a machine that slowly pulls the top and bottom ends of the bat, ensuring that the handle is a tight, secure fit.

A custom machine pulls the bat in different directions to ensure strength

That process takes about 10 minutes. The bats are then put on a machine that applies glue to the top interior of the barrel so the end cap can be attached. Glue is applied by hand to the area where the knob will be fitted in place. The knob is then screwed in, and a separate machine inserts a pin to keep the knob in place during use. Finally, the bats are taken to a machine that rotates them, which allows for the grip tape to be applied. A skilled technician applies the grip tape to the spinning bat.

And there you have it—the bat will now be packaged and shipped out. In a busy month, Demarini will turn out 2,400 bats each and every day.

The finished product: a custom Demarini bat boxed up and ready to ship

The bat of your dreams doesn’t come cheap. Choosing a custom bat over a standard model will cost you roughly an extra $120. To create your own Demarini custom bat, head to demarinicustombats.com.

My customized bat

RECOMMENDED FOR YOU

MOST POPULAR

The Bat of Your Dreams: Inside Demarini’s New Custom Bat Line

![]()

Baseball players always find a way to make equipment their own. Ballplayers have worn the same basic uniform (hat, jersey, pants, spikes, etc.) for the last century, yet they’ve found a surprising amount of creative freedom within the traditional garb of America’s pastime.

How do you wear your pants? How do you brim your hat? Do you like wristbands? Do you unbutton your jersey? Do you wear one batting glove? Two? No gloves at all? Small cosmetic details might seem unimportant to a spectator, but the extra sense of comfort or confidence they bring can mean the world to a player. In a sport where failing seven out of 10 times will put you in the Hall of Fame, confidence is an extremely valuable—yet elusive—part of the game. Gear isn’t just about looking good, it’s about feeling good as well.

With the launch of Demarini’s custom bat line, players now have another way to express themselves through their gear. In the past, every specific bat model looked the same—same color scheme, graphics, etc. If you wanted to make your bat unique, the best you could do was scribble on it with a sharpie or roll the handle with a different colored grip tape. Now, you can alter a bat’s color scheme to fit your taste—and you can add personal touches like your nickname, team name, numerals, etc.

STACK visited Demarini headquarters in Hillsboro, Oregon to find out more about their custom bat line.

Your Bat, Your Way

Customization is in Demarini’s DNA. The company was founded in 1989, when founder Ray Demarini started making custom bats in his shed for friends and teammates. Fast forward to today, and Demarini is one of the top bats in baseball and softball. Their focus is innovation driven by direct player feedback. College baseball powerhouses like Arizona State, LSU and Vanderbilt, as well as college softball juggernauts like Oregon, Michigan and Baylor, will swing Demarini bats in 2015.

It seems like custom bats would be a no-brainer. We’ve been able to customize and personalize our favorite sneakers for over 15 years. So why haven’t we been able to customize our bats until now? It turns out that making a bat is a complicated process, only further complicated by throwing customization into the mix. That’s why Demarini is the first company to offer truly customizable bats.

The custom bat website, demarinicustombats.com, is intuitive. You start by picking the model you like. Currently, only one model is available for both baseball and slow pitch. Fastpitch bats will become available for customization in April. Demarini says that more models will become available for customization shortly, and the number of customization options will also expand, meaning more colors, logos, graphics, fonts, etc.

Once you choose your model, you run through a checklist of bat components—barrel, end cap, handle, grip, graphics, etc.—picking the color you want for each. Toward the end of the process, you can insert a logo or custom text onto both the end cap and the knob. It’s a simple, fun process, and you can easily kill an hour or two bringing different design ideas to life. Once you digitally purchase your custom creation, the specifications of the bat are sent to the Demarini factory. Then the real work begins.

The Bat Cave

Demarini’s operations are spread across two buildings a couple of miles apart. The first building, known as D1, houses the company’s administrative offices, research & development, engineering, testing, shipping and final manufacturing. The second building, known as D2, is the main manufacturing facility. The fact that Demarini has all of this in one place makes them agile—they can dream up a bat, create it and test it in a single day.

Every Demarini bat starts at D2 in the form of a hefty, hollow chunk of cylindrical aluminum.

The building block of every Demarini bat

The bats are then sanded, smoothed and shined to remove any blemishes and imperfections. They also receive an interior winding that allows for the end cap to be screwed on later.

A Demarini bat after it’s been sanded and shined

Next, the bats are lined up and sent past a machine that applies a base coat, which helps the colored paint and graphics stick to the bat. The next step is different for custom bats and standard model bats. The standard model bats continue down the line and are sprayed with an identical base color. The photo below shows some 2015 Voodoo Overlord models being painted.

Paint being applied to a crop of Demarini 2015 Voodoo Overlords

Since each custom bat has a different color scheme, they cannot be painted en masse like the standard models. They are painted individually. Nearly 20 paint colors are currently available, including outlandish options like Vegas Gold and Neon Green. Paint used for Demarini’s custom bats is first hand-mixed and then applied by hand.

A batch of paint being mixed for use on a Demarini custom bat

The hand-painted approach obviously takes longer. In fact, a Demarini custom bat takes twice as long to make, with twice as many hands touching it, as a standard model bat. That extra TLC is a big reason why no company has offered custom bats until now. Demarini believes the extra time is well spent when the goal is to give players what they want.

After a bat is painted, it’s put into a low-heat, industrial size oven for roughly 45 minutes while the paint dries. Next, the bat graphics are applied. Since a user can pick different colors for the lettering and graphics on a custom bat, each graphic must be carefully applied by hand.

Demarini custom graphics prior to being applied to a bat

This requires a delicate touch. Graphic appliers must go through six months of training. After the graphics are masterfully applied, another clear coating is put on the bat, which allows the paint and graphics to stay crisp and clear despite the immense beating the bat takes. The coating is also a UV protectant, ensuring the paint won’t fade after a couple of days in the summer sun. After that, the bat is carefully packaged so it can be transported to D1 for final assembly.

Back at D1, the bat handles are attached by a machine that applies a strong glue and affixes them to the bat barrels. The only parts of Demarini’s bats that aren’t built in-house are the end caps, knobs and handles. These are done by a nearby Hillsboro manufacturer. After that, the bat is placed on a machine that slowly pulls the top and bottom ends of the bat, ensuring that the handle is a tight, secure fit.

A custom machine pulls the bat in different directions to ensure strength

That process takes about 10 minutes. The bats are then put on a machine that applies glue to the top interior of the barrel so the end cap can be attached. Glue is applied by hand to the area where the knob will be fitted in place. The knob is then screwed in, and a separate machine inserts a pin to keep the knob in place during use. Finally, the bats are taken to a machine that rotates them, which allows for the grip tape to be applied. A skilled technician applies the grip tape to the spinning bat.

And there you have it—the bat will now be packaged and shipped out. In a busy month, Demarini will turn out 2,400 bats each and every day.

The finished product: a custom Demarini bat boxed up and ready to ship

The bat of your dreams doesn’t come cheap. Choosing a custom bat over a standard model will cost you roughly an extra $120. To create your own Demarini custom bat, head to demarinicustombats.com.

My customized bat